Fill out the online form to be contacted by a salesperson

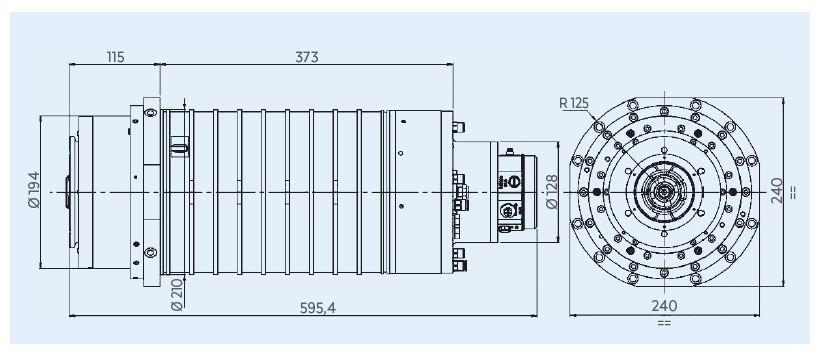

MX-2 38/3 12 100A

High-power electrospindle for milling and drilling of stainless steel, cast iron, aluminum and metals. Compact design allows installation on cnc machine, milling heads with direct drive (torque motors) or mechanically.

- HSK 100A tool holder with ball bearings allows to this electrospindle to carry out heavy roughing operations

- 15000 RPM max speed with ball bearings oil lubrication allows to carry out surface finishing operations

- On-board triaxial accelerometer: the sensor measures the vibrations in all directions

- It is available the axial shaft displacement sensor as optional. It is able to report to the machine the spindle nose movement during the processing, allowing the machine to correct the tool positioning

The spindle is equipped with a rotary joint that allows to cool the tool during the processing through the flow of refrigerant fluid through the shaft (CTS) or through minimal air-oil lubrication (MQL)

Around the electrospindle nose there is a tool cooling distributor enable to cool it in each machine way

Front and back bearings are monitored from two temperature sensors able to signal abnormal operating temperatures

| Specifications | ||

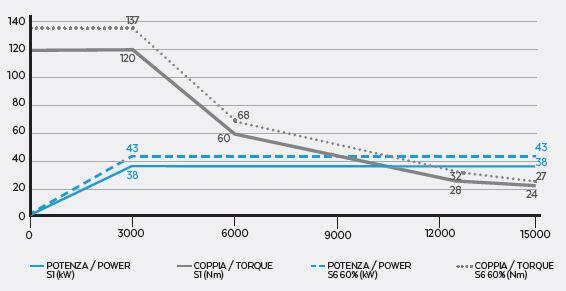

| Max power S1/S6 | kW | 38/43 |

| Nominal power | rpm | 3000 |

| Max rotation speed | rpm | 12000 |

| Max torque S1/S6 | Nm | 120/137 |

| Current S1/S6 | A | 109/124 |

| Voltage | V | 380 |

| Type of electrospindle | Synchronous | |

| Weight | kg |

110 |

| Equipment | ||

| Tool taper | HSK100A | |

| Type of tool changer | Automatic | |

| Bearings | Ceramic - grease lubrication for life | |

| Cooling | Liquid | |

|

Sensors |

S1 (Tool grip) S2 (Collet open) S5 (Piston back) |

|

| Release cylinder | Idraulic double-action | |

|

Other specifications |

Encoder 1 Vpp | |

|

Pressurised labyrinth |

||

| Optional |

| Axial shaft displacemen sensor |

| Ball bearings oil lubrication (15.000 rpm) |

Fill out the online form to be contacted by a salesperson