Fill out the online form to be contacted by a salesperson

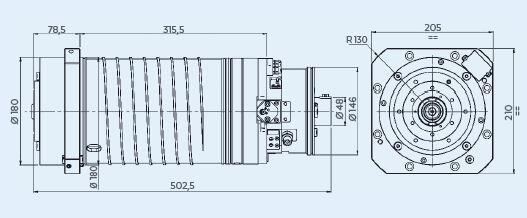

MX-2 41/4.5 24 63A

High-power electrospindle for milling and drilling on metal, aluminum and composite materials. Compact design allows installation on cnc machine, milling heads with direct drive (torque motors) or mechanically.

- 24000 RPM max speed with grease lubrication makes this model suitable for the processing of composite materials for aerospace components

- On-board triaxial accelerometer: the sensor measures the vibrations in all directions

The spindle is equipped with a rotary joint that allows to cool the tool during the processing through the flow of refrigerant fluid through the shaft (CTS) or through minimal air-oil lubrication

Around the electrospindle nose there is a tool cooling distributor enable to cool it in each machine way

Front and back bearings are monitored from two temperature sensors able to signal abnormal operating temperatures

| Specifications | ||

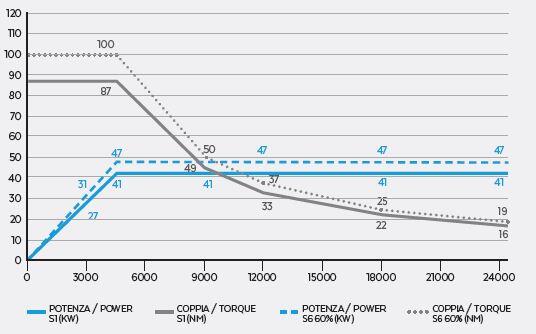

| Max power S1/S6 | kW | 41/47 |

| Nominal power | rpm | 4.500 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 87/100 |

| Current S1/S6 | A | 136/156 |

| Voltage | V | 380 |

| Type of electrospindle | Synchronous 6 Poles | |

| Weight | kg |

70 |

| Equipment | ||||

| Tool taper | HSK63A | |||

| Type of tool changer | Automatic | |||

| Bearings | Ceramic - grease lubrication for life | |||

| Cooling | Liquid | |||

|

Sensors |

S1 (Tool grip) S2 (Collet open) S5 (Piston back) |

|||

| Release cylinder | Idraulic double-action | |||

|

Other specifications |

Encoder 1 Vpp | |||

| Vibration and speed monitoring sensor | ||||

| Bearings temperature sensor | ||||

| Rotary joint (80 bar) | ||||

|

Pressurised labyrinth |

||||

| Optional |

| Axial shaft displacemen sensor |

| Ball bearings oil lubricant (24.000 rpm) |

Fill out the online form to be contacted by a salesperson