Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened

ORBITAL M

Birotary head for high-precision milling of stainless steel molds and cast iron, aluminum and metal components, for the automotive, NEV (new electric vehicle), Railway and Aerospace sectors. The birotary head can be paired with Hiteco’s spindle: MX-2 42/6 24, MX-2 47/3 12 and MX-2 60/3 12

- Two axis direct drive allows to guarantee a higher surface finishing level and a higher positioning speed than conventional drive heads

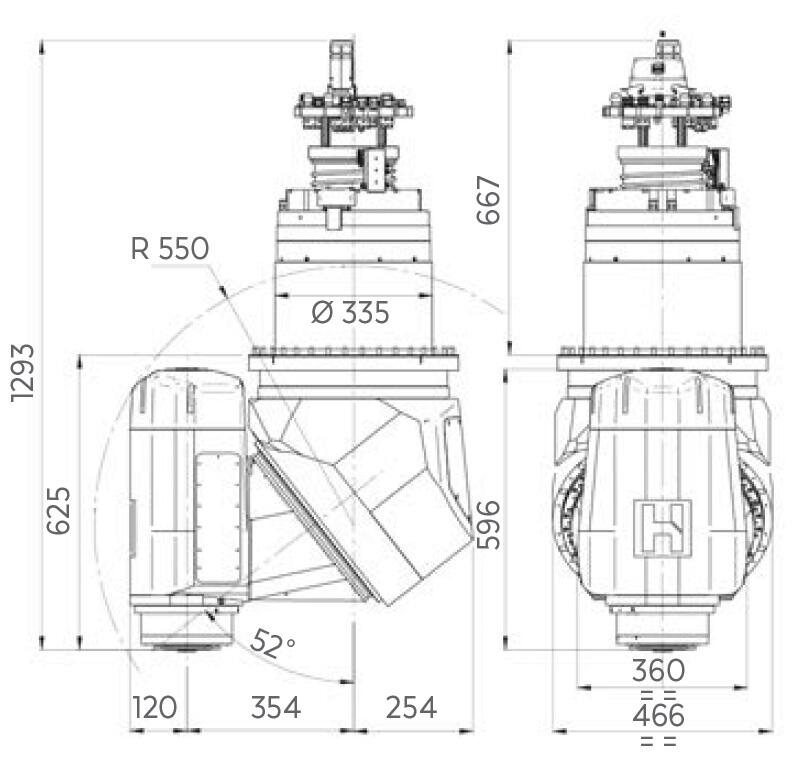

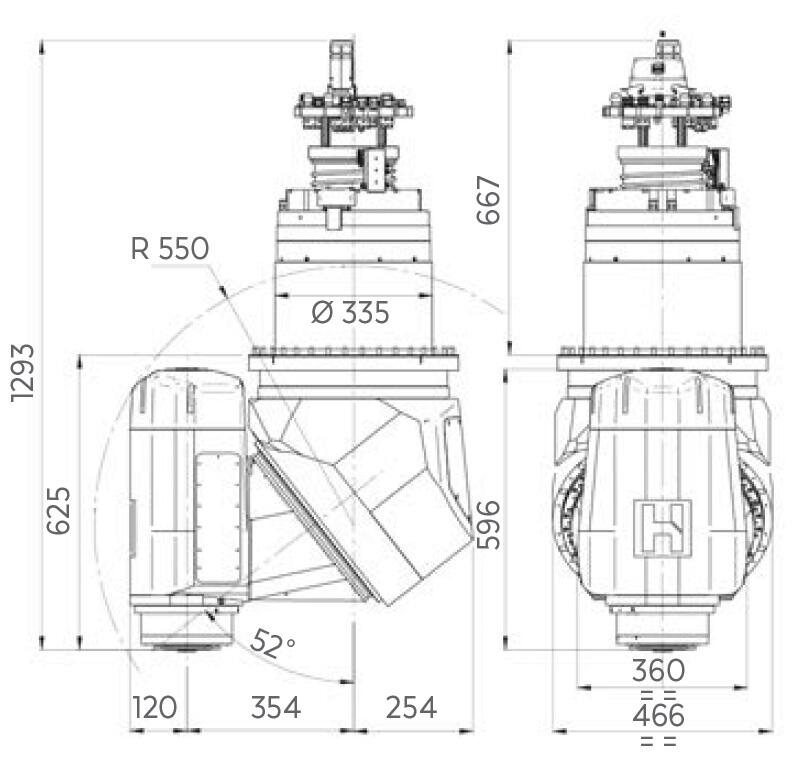

- The birotary head features an angle of incidence of the axes of 50° and the presence of an offset of 354 mm between the C axis and the spindle axis in a vertical position.

- The high locking torque of the C-axis and A-axis brakes ensure the rigidity necessary to carry out heavy CNC roughing operations

- The c-axis is equipped with an axial-radial bearing with large diameter rollers combined with counter-support roller bearings to increase the stiffness of the joint

- Direct drive of the axes made with torque motors with high torque density, high overload capacity and low losses

- Electrospindle and torque motor cooling circuit designed to avoid thermal deformations, guaranteeing maximum cutting precision during machining

- The wide range of electrospindles available allows the use of the birotary head for the production of components made of different materials

The presence of an offset of 354 mm between the C axis and the spindle axis in a vertical position allows the working volume of the machine to be increased with the same axis travel

Layout

Technical data

| Technical Specifications | ||

| B AXIS | C AXIS | |

| Axis motor | Direct drive | Direct drive |

| Rated torque | 560 Nm | 787 Nm |

| Peak torque | 1030 Nm | 1560 Nm |

| Measuring system | Incremental Encoder | Incremental Encoder |

| Accuracy of graduation | ± 3,8" | ± 2" |

| Type of clamping | Pneumatic | Hydraulic |

| Clamping torque | 3720 Nm | 4000 Nm |

| Max axis rotation | ± 180° | ± 360° |

| Head fitting diameter | ø 335 | |

| Spindle fitting diameter | ø 210 (ø 180) | |

| Weight | 650 kg | |

| Electrospindles |

MX-2 42/6 24 63A MX-2 47/3 12 100A MX-2 60/3 12 100A |

|

Media

Configuration

Request information

Contact us

Fill out the online form to be contacted by a salesperson