Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened

QD-2 8/12 40 32E

- Suitable for machining aluminium, plastic and light alloys

- High power at high RPMs (up to 40,000 RPM)

- iM SMART SENSOR: speed, vibrations and temperature directly to your PC (link)

LONG LIFE SPINDLE

Variable bearings pre-load system with springs to allow the spindle to machine without overheating

CONFIGURABILITY

With the same layout there are a wide range of power options available (up to 8 kW) and optionals to meet different types of machining operations

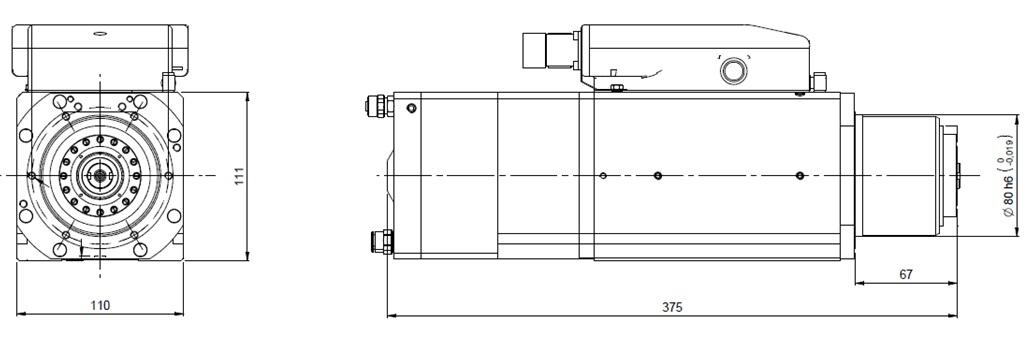

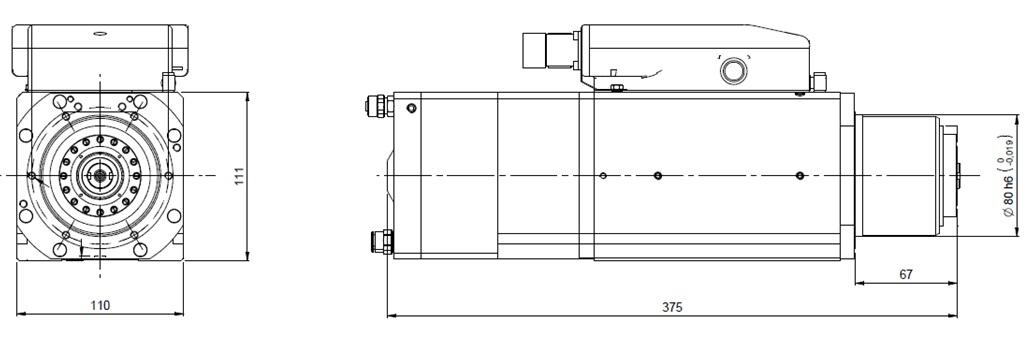

Layout

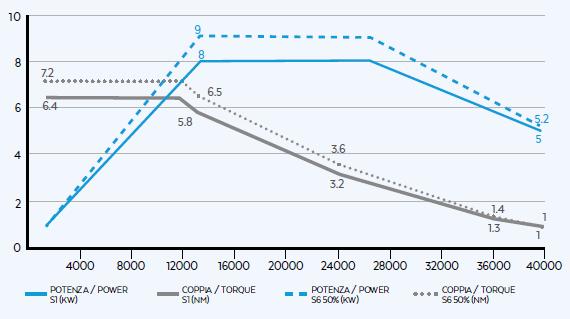

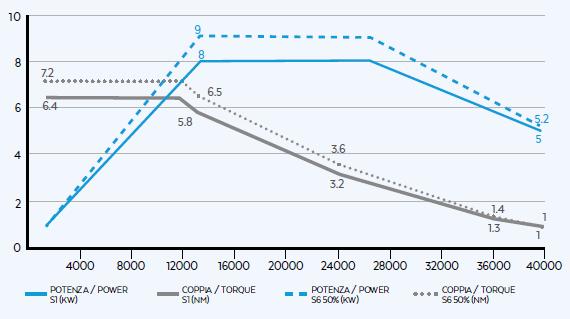

Performance

Technical data

| Specifications | ||

| Max power S1/S6 | kW | 8/9 |

| Nominal power | rpm | 12000 |

| Max rotation speed | rpm | 40000 |

| Max torque S1/S6 | Nm | 6.4/7.2 |

| Current S1/S6 | A | 24/26 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg | 17 |

| Equipment | ||

| Tool taper | HSK 32E | |

| Type of tool changer | Automatic | |

| Bearings | Ceramic - grease lubrication for life | |

| Cooling | Liquid | |

| ESD (Electric Static Discharge) | ||

|

Sensors |

S1 (Tool grip) S5 |

|

| Release cylinder | Pneumatic double-action | |

|

Other specifications |

Taper blow | |

| Pressurised labyrinth | ||

| CC circular connection | ||

| Optional |

| Plug&Play PP connection |

| Dual Voltage 220V-380V |

| Encoder 1Vpp or TTL |

| Temperature monitoring sensor (IM Smart Sensor) |

| Bearings temperature monitoring sensor (IM Smart Sensor) |

| Vibration monitoring sensor (IM Smart Sensor) |

| Speed monitoring sensor (IM Smart Sensor) |

Configuration

QD-2 8/12 40 HSK 32E NL CC

Technical sheet

Download

Layout

Download

3D

Request file

QD-2 8/12 40 HSK32E NL CC EN

Technical sheet

Download

Layout

Download

3D

Request file

QD-2 8/12 40 HSK32E NL SC

Technical sheet

Download

Layout

Download

3D

Request file

Request information

Contact us

Fill out the online form to be contacted by a salesperson