Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened

QX Series

- Suitable for machining wood and aluminium

- Optimal layout for bi-rotation heads at 90° and 50°

- Encoder version available

- Compressed air cooled version available

- iM SMART SENSOR: speed, vibrations and temperature directly on your PC

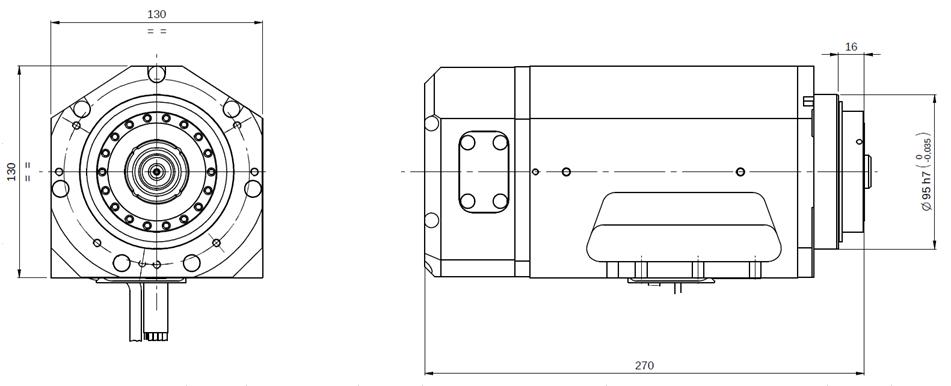

Layout

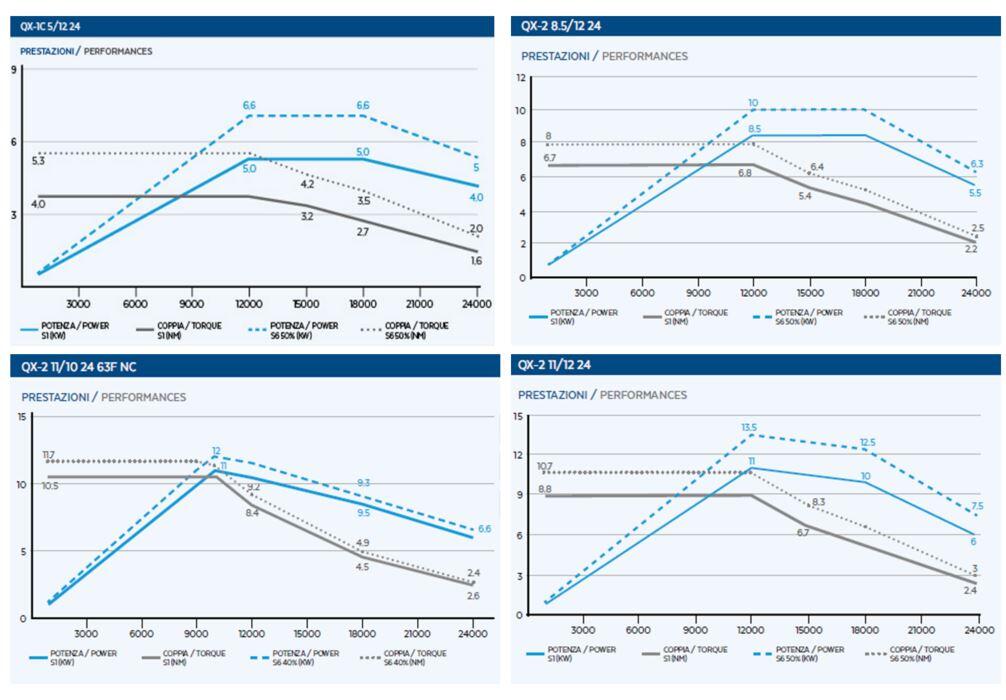

Performance

Technical data

QX-2 8.5/12 24

| Specifications | ||

| Max power S1/S6 | kW | 8.5/10 |

| Nominal power | rpm | 12000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 6.8/8 |

| Current S1/S6 | A | 20/22 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg | 18 |

QX-2 11/12 24

| Specifications | ||

| Max power S1/S6 | kW | 11/13.5 |

| Nominal power | rpm | 12000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 8.8/10.7 |

| Current S1/S6 | A | 24.5/29.5 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg | 19 |

QX-2 11/10 24

| Specifications | ||

| Max power S1/S6 | kW | 11/12 |

| Nominal power | rpm | 10000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 10.5/11.7 |

| Current S1/S6 | A | 29/31 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 6 Poles | |

| Weight | kg | 21 |

QX-1C 5/12 24

| Specifications | ||

| Max power S1/S6 | kW | 5/7 |

| Nominal power | rpm | 12000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 4/5.6 |

| Current S1/S6 | A | 11/13.5 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Cooling | Compressed air | |

| Weight | kg | 19 |

| Equipment* | ||

| Tool taper | HSK 63F | |

| Type of tool changer | Automatic | |

| Bearings | Ceramic - grease lubrication for life | |

| Cooling | Liquid | |

|

Sensors |

S1 (Tool grip) S5 (Piston back) |

|

| Release cylinder | Pneumatic single-action | |

|

Other specifications |

Plug & play PP connection | |

| Taper blow | ||

| Pressurised labyrinth | ||

* all models

| Optional* |

| Encoder 1Vpp or TTL |

| Speed monitoring sensor (iM Smart Sensor) |

| Bearings temperature monitoring sensor (iM Smart Sensor) |

| Vibration sensor (iM Smart Sensor) |

| Power supply 220 V** |

| Anti-rotation sleeves |

* all models

** only for 8.5 and 11 kW versions

Media

Configuration

QX-2 8.5/12 24 HSK63F NC

Technical sheet

Download

Layout

Download

3D

Request file

QX-2 8.5/12 24 HSK63F NC 4S

Technical sheet

Download

Layout

Download

3D

Request file

QX-2 11/10 24 HSK63F NC

3D

Request file

QX-2 11/12 24 HSK63F NC

Technical sheet

Download

Layout

Download

3D

Request file

QX-1C 5/12 24 HSK 63F NC SC

Technical sheet

Download

Layout

Download

3D

Request file

Request information

Contact us

Fill out the online form to be contacted by a salesperson