Fill out the online form to be contacted by a salesperson

iM Smart Sensor

The iM Smart Sensor is an intelligent sensor that constantly monitors the machining conditions of the spindle it is installed on.

It can support the whole production process, monitoring the main quantities that the spindle works on: vibration and temperature.

This process monitoring instrument lets users easily identify malfunctions and consequently reduce unexpected machine down times.

iM Smart Sensor is available for Powertech electrospindles (3-axis machines) and for Robotech electrospindles (5-axis machines)

Preventive maintenance: machine down times can be prevented by monitoring the spindle's operation over time

Safety: the sensor immediately communicates if the operating conditions are too demanding or dangerous

Precision: the sensor's exclusive technology monitors the vibrations produced by the electrospindle and ignores those produced by the rest of the machine

| Technical Specifications | |

| Accelerometer | Triaxial with three orthogonal axes X, Y and Z |

| Sensor type | MEMS |

| Field of measurement | ±16 G (156 m/sec^2) |

| Bandwidth | 1000 Hz |

| Resolution | 0,125 g/sample |

| Operating temperature | From 5 to 85° |

| Impact resistance | 3000 G (29400 m/sec^2) |

| Connectivity |

Modbus on RS485 |

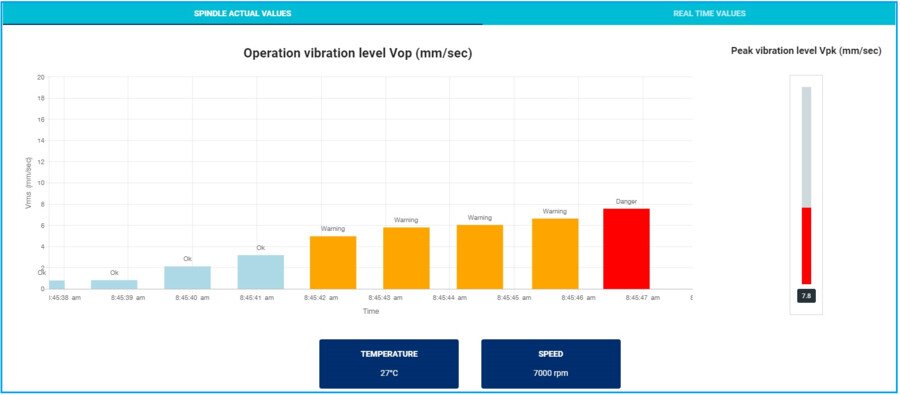

- Spindle actual values: it is used to monitor, through an intuitive graph and coloured histograms, the vibration level, the rotation speed and the temperature of the electrospindle bearings.

- Spindle state: state indicator that checks whether the machining conditions of the electrospindle are optimal or not.

- Real time values: graph that displays the vibration level, acceleration and bearings' temperature values over time.

Fill out the online form to be contacted by a salesperson