Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened

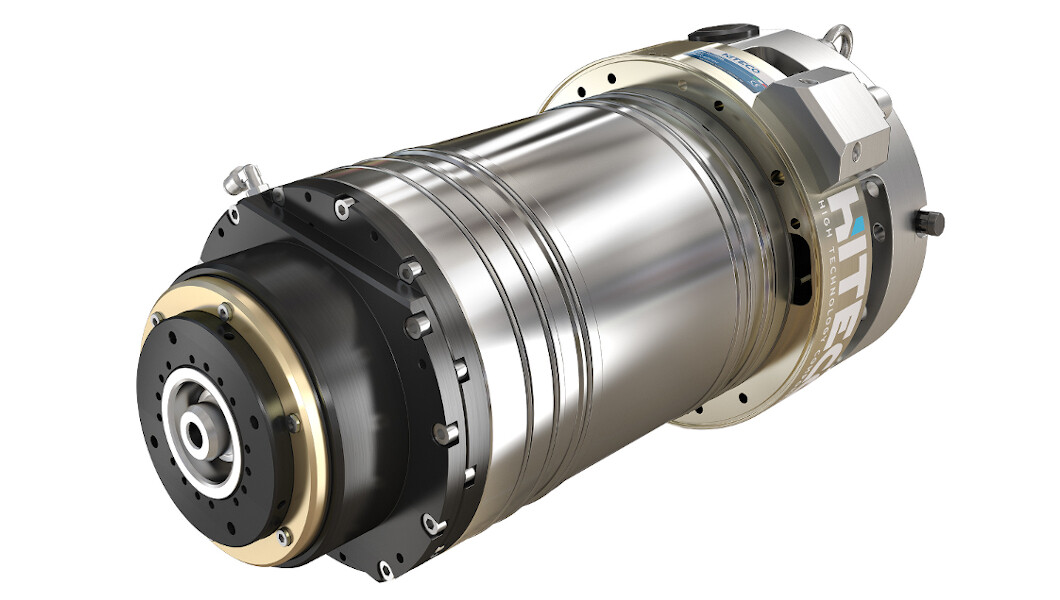

KX-2 32/4.5 24 63A

- Suitable for processing aluminum alloys and metal finishes

- High torque density up to 100 Nm

- Front bearings cooling circuit on the HIGH SPEED version

- Same housing available for each model

VERSATILITY

Available in HIGH SPEED (up to 24000 rpm) and HIGH TORQUE version (torque up to 112 Nm in S6)

24000 RPM

Speed achievable with long life bearings, therefore, dedicated lubrication control units are avoided

SIMPLIFIED MACHINE INTEGRATION

Pneumatic release cylinder for a considerable reduction of the pneumatic system

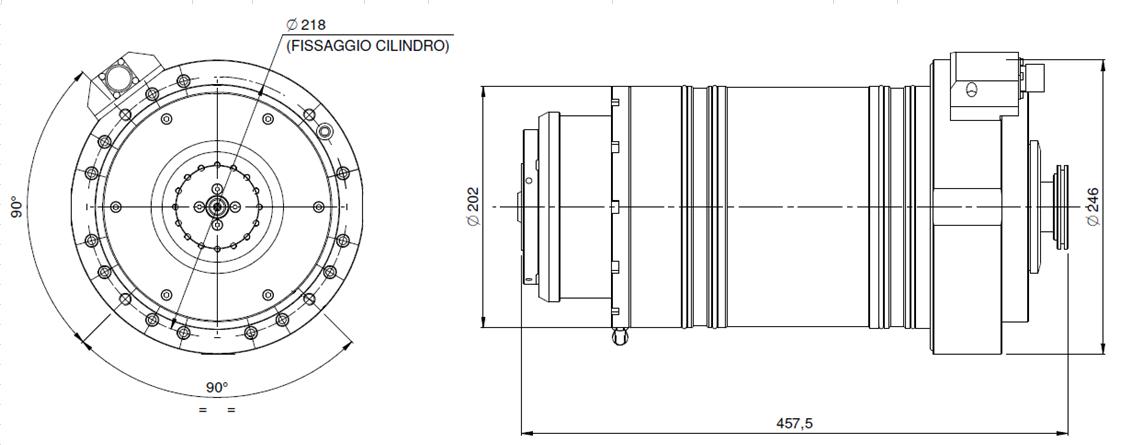

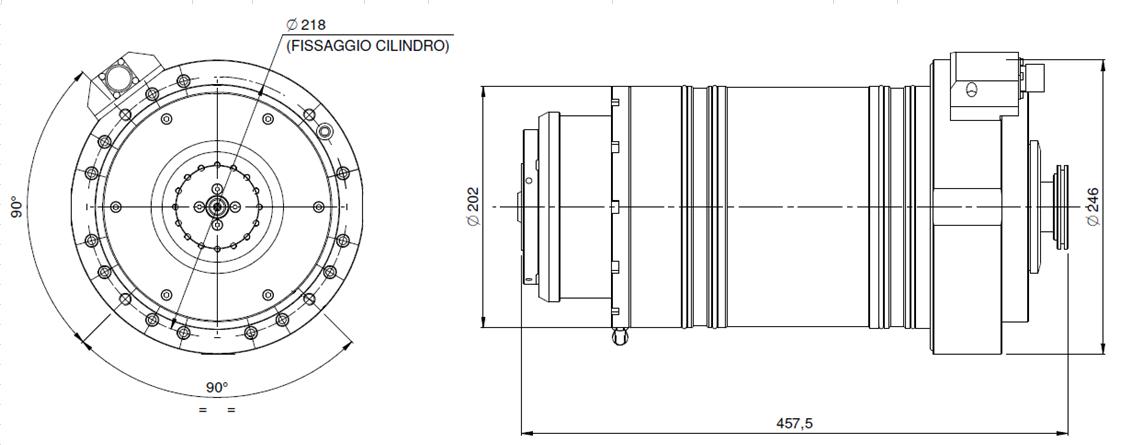

Layout

Performance

Technical data

| Specifications | ||

| Max power S1/S6 | kW | 32/32 |

| Nominal power | rpm | 4500 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 68/100 |

| Current S1/S6 | A | 73/113 |

| Voltage | V | 400 |

| Type of electrospindle | Synchronous 6 Poles | |

| Weight | kg |

100 |

| Equipment | ||

| Tool taper | HSK63A | |

| Type of tool changer | Automatic | |

| Bearings | Ceramic - grease lubrication for life | |

| Cooling | Liquid | |

|

Sensors |

S1 (Tool grip) |

|

| Release cylinder | Pneumatic single-action | |

|

Other specifications |

Encoder 1 Vpp | |

| Pressurised labyrinth | ||

| Optional |

| Air Tool |

| Long nose |

| Taper blow |

| CTS lubrication |

| Oil Mist/MQL |

Configuration

KX RANGE

Technical sheet

Download

3D

Request file

KX-2 32/4.5 24 HSK63A NC ES CS

Technical sheet

Download

3D

Request file

Related products

Request information

Contact us

Fill out the online form to be contacted by a salesperson