Fill out the online form to be contacted by a salesperson

Hiteco Connect

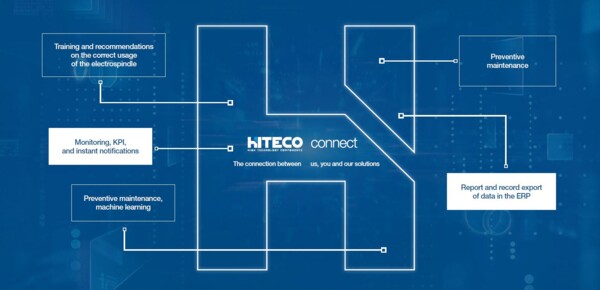

HITECO CONNECT: The connection between us, you and our solutions

Thanks to the Hiteco Smart Spindle and Hiteco Connect you will able to monitor the status of your spindle in real time, visualize statistics and plan preventive maintenance avoiding machine down-time! The Hiteco Smart Spindle monitors all the working conditions and generates messages in order to increase the productivity and the uptime of your machine. reducing operating costs, and avoiding down-times. The Hiteco Connect is the human machine interface which lets the spindle communicate with you sharing data, relevant events,warnings and much more by popup messages on your device screen: smartphone, tablet or PC. Hiteco connect is a software platform common to all the Hiteco Smart products (including Bi-rotative heads).

With Hiteco connect you can have all the Spindle data and messages available at glance!

The data sent from the Smart Spindle are analyzed in real time, to show all the necessary data to the operator, 24/7.

With Hiteco Connect you can access a wide range of digital services that accompany your product throughout its life cycle. Monitor the condition and remaining life of your spindle, assess its performance and avoid machine stops.

Preventive maintenance: machine down times can be prevented by monitoring the spindle's operation over time

Safety: the sensor immediately communicates if the operating conditions are too demanding or dangerous

Precision: the sensor's exclusive technology monitors the vibrations produced by the electrospindle and ignores those produced by the rest of the machine

Fill out the online form to be contacted by a salesperson