Bitte füllen Sie das Formular aus, um weitere Informationen zu erhalten

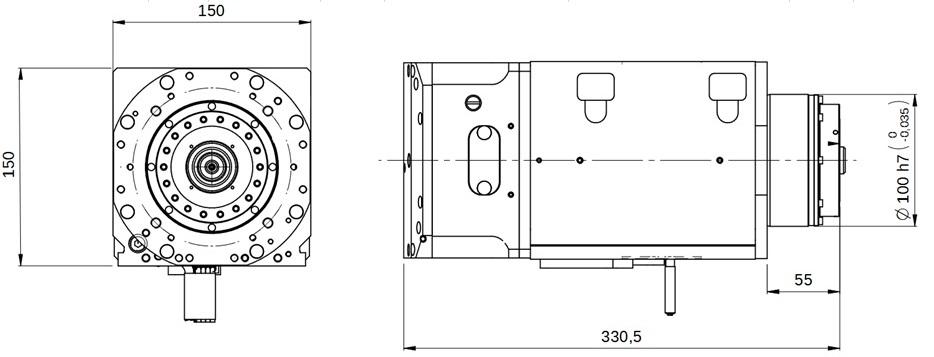

HX Series

- Suitable for machining wood, aluminium and composite materials

- Optimal layout for bi-rotation heads at 90° and 50°

- Possibility of using units on the front flange

- iM SMART SENSOR: speed, vibrations and temperature directly on your PC

CONFIGURABILITY

With the same layout there is a wide range of power options available (up to 20 kW) to meet different types of machining operations

STIFFNESS

5 bearings in the long nose version for greater precision in demanding machining operations

VERSATILE LAYOUT

Square housing optimised for maximum versatility in different applications (bi-rotary bi-upright, single upright heads and 3-axis machines)

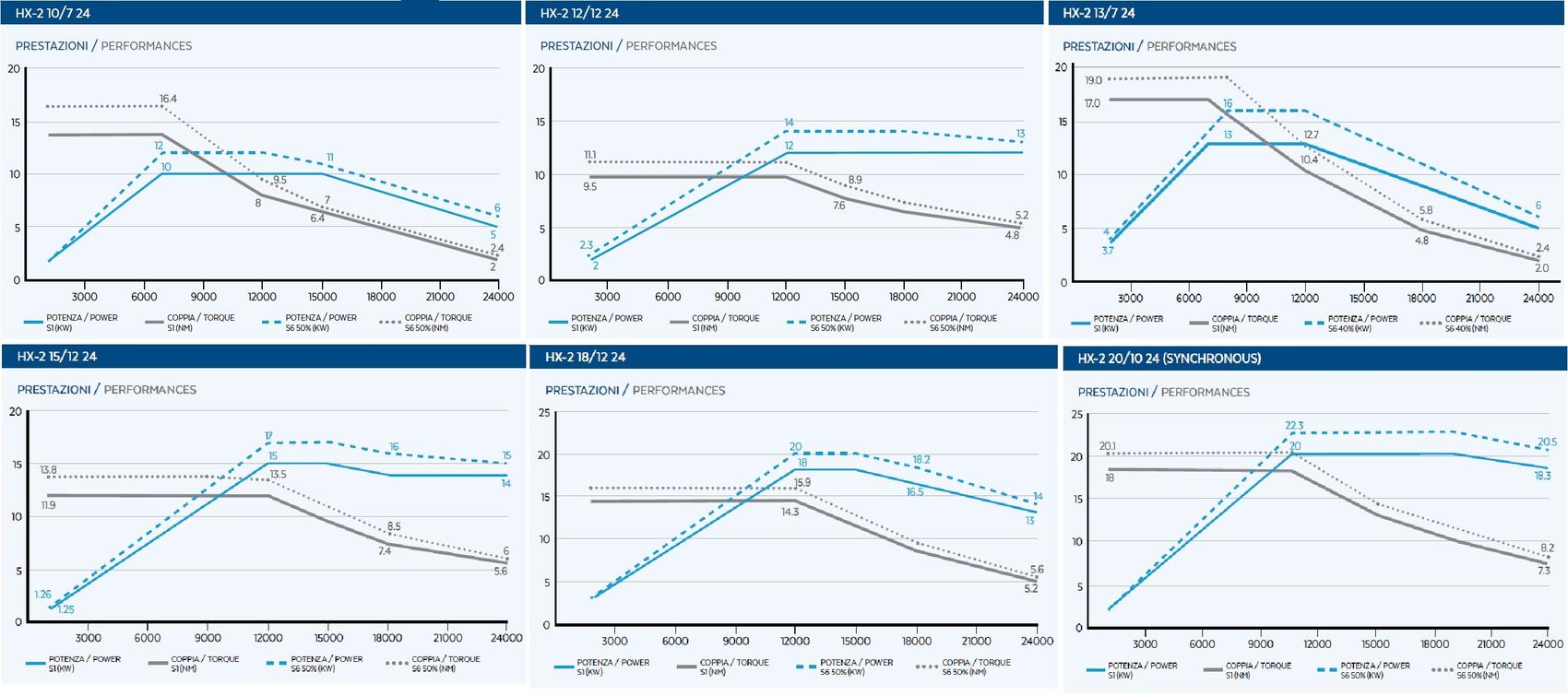

HX-2 10/7 24

| Specifications | ||

| Max power S1/S6 | kW | 10/12 |

| Nominal power | rpm | 7000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 13.6/16.4 |

| Current S1/S6 | A | 21/25 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg |

25 |

HX-2 13/7 24

| Specifications | ||

| Max power S1/S6 | kW | 13/16 |

| Nominal power | rpm | 7000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 17/19 |

| Current S1/S6 | A | 35/39 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 6 Poles | |

| Weight | kg |

23 |

HX-2 12/12 24

| Specifications | ||

| Max power S1/S6 | kW | 12/14 |

| Nominal power | rpm | 12000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 9.5/11.1 |

| Current S1/S6 | A | 26/29 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg |

25 |

HX-2 15/12 24

| Specifications | ||

| Max power S1/S6 | kW | 15/17 |

| Nominal power | rpm | 12000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 11.9/13.8 |

| Current S1/S6 | A | 30/33 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg |

25 |

HX-2 18/12 24

| Specifications | ||

| Max power S1/S6 | kW | 18/20 |

| Nominal power | rpm | 12000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 14.3/15.9 |

| Current S1/S6 | A | 35/38.5 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg |

25 |

HX-2 20/10 24 Synchronous

| Specifications | ||

| Max power S1/S6 | kW | 20/22.3 |

| Nominal power | rpm | 10000 |

| Max rotation speed | rpm | 24000 |

| Max torque S1/S6 | Nm | 17.8/20.1 |

| Current S1/S6 | A | 48/50 |

| Voltage | V | 380 |

| Type of electrospindle | Synchronous 4 Poles | |

| Weight | kg |

25 |

| Equipment* | ||

| Tool taper | HSK 63F/63A ** | |

| Type of tool changer | Automatic | |

| Bearings | Ceramic - grease lubrication for life | |

| Cooling | Liquid | |

|

Sensors |

S1 (Tool grip) S5 (Piston back) |

|

| Release cylinder | Pneumatic single-action | |

|

Other specifications |

Taper blow | |

| Pressurised labyrinth | ||

| CC circular connectors | ||

* all models

** HSK 63A for 20 kW model

| Optional* |

| HSK 63E/63A |

| Long nose |

| Air tool |

| Encoder 1Vpp or TTL |

| Oil Mist/MQL |

| Bearings temperature monitoring sensor (iM Smar Sensor) |

| Speed monitoring sensor (iM Smar Sensor) |

| Vibration sensor (iM Smar Sensor) |

| CC machine side circular connectors |

| Anti-rotation sleeves |

* all models

Bitte füllen Sie das Formular aus, um weitere Informationen zu erhalten