Request information

Fill out the online form to be contacted by a salesperson

Thank you Your message has been sent.

Error! Something wrong has happened

GX-80 I40

Electrospindle for stone and glass processing with high-speed asynchronous motor. Ideal for milling, drilling, cutting out, polishing, bevelling and engraving. Compact design to be installed on CNC machines with vertical plane (drills), horizontal and robots.

- Tools holder available: BT40 and ISO40 Hiteco

- Max speed 12000 RPM. With ceramic ball bearings option 15000 RPM

- Air cooling

- Tool holder doesn't need drive keys for an easy manage of the tool changer

- Main components in INOX steel

- Hiteco rotating water joint for tools cooling

- Sleeve tool cooling

- Integrated 1Vpp or TTL encoder (opt.)

- Joint Monitoring Sensor (opt.)

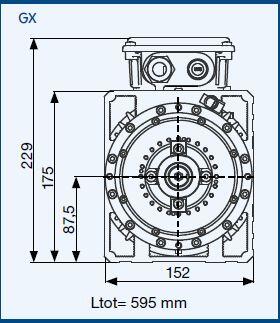

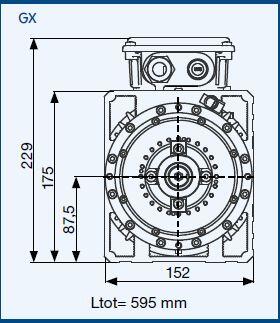

Layout

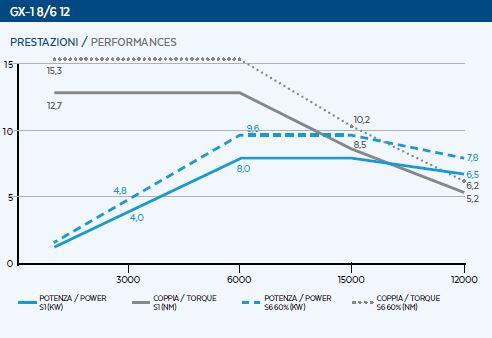

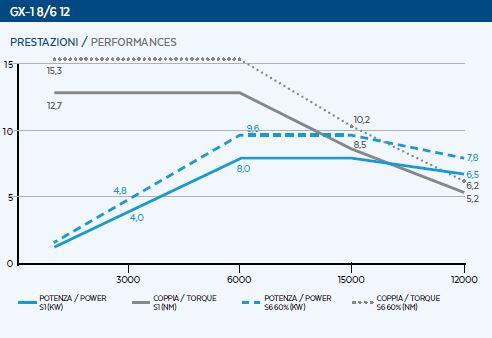

Performance

Technical data

| Specifications | ||

| Max power S1/S6 | kW | 8/9.5 |

| Nominal power | rpm | 6000 |

| Max rotation speed | rpm | 12000 |

| Max torque S1/S6 | Nm | 13/15 |

| Current S1/S6 | A | 17/20 |

| Voltage | V | 380 |

| Type of electrospindle | Asynchronous 4 Poles | |

| Weight | kg | 58 |

| Equipment | ||

| Tool taper | ISO40 | |

| Type of tool changer | Automatic | |

| Cooling | Shaft-driven fan | |

|

Sensors |

S1 (Tool grip) S5 (Piston back) |

|

| Release cylinder | Pneumatic double-action | |

|

Other specifications |

Water tool cooling | |

| Pressurised labyrinth | ||

| Optional |

| iM Smart Sensor |

| 15000 rpm Max Speed with ceramic ball bearings |

| Encoder 1Vpp or TTL |

| Joint Monitoring Sensor |

| Pneumatic index |

| ISO40 DIN |

| Accessories |

| Sleeve tool cooling |

| C-axis available |

Configuration

Request information

Contact us

Fill out the online form to be contacted by a salesperson